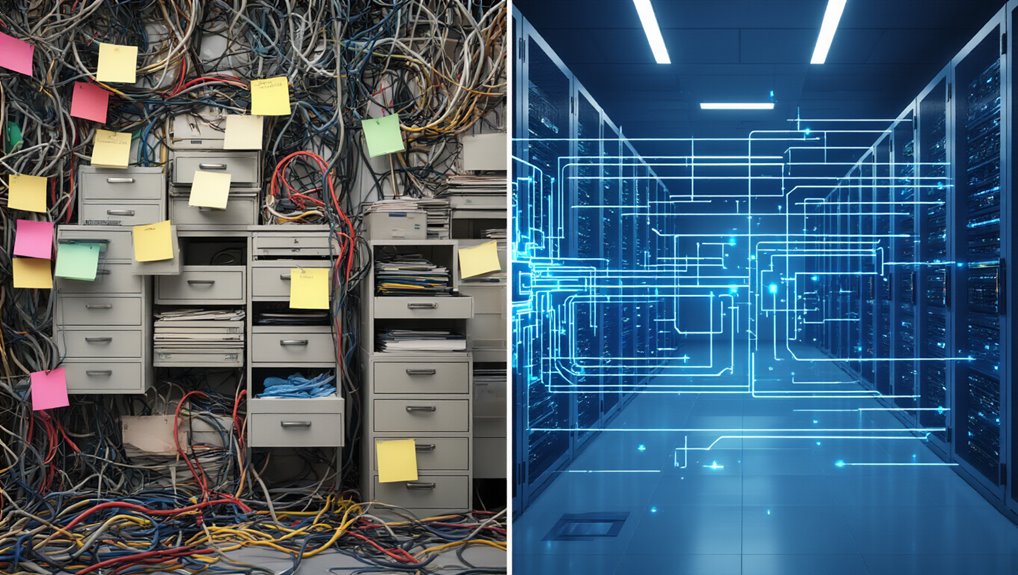

While organizations increasingly recognize the competitive advantage of streamlined supplier collaboration, many continue to struggle with outdated legacy supplier portals that impede rather than enhance business relationships. These aging systems create integration bottlenecks through brittle point-to-point connections that frequently break during upstream system changes.

Legacy supplier portals create brittle connections that break during system changes, undermining the very collaborations they aim to enhance.

Without real-time data synchronization, companies resort to manual spreadsheet reconciliations, increasing errors and delaying critical decisions. Teams operate with partial data across systems, causing mismatches that create significant downstream friction.

Legacy portals typically lack modern communication features like in-app chat and notifications, forcing reliance on email threads that fragment important conversations. This creates information silos between departments and suppliers, notably extending problem resolution cycles.

The absence of unified views across PLM, ERP, and MES systems reduces traceability precisely where important decisions occur.

The automation deficit in older portals presents substantial operational costs. Without AI-driven escalations for unacknowledged specification changes or at-risk orders, teams remain perpetually reactive. Modern supplier collaboration solutions can automate procurement processes, resulting in 15% to 40% cost savings.

Rigid rule engines require IT intervention for even minor business logic adjustments, hampering agility when market conditions change. Routine tasks like order tracking and invoice matching consume excessive manual resources that could be deployed more strategically.

User experience challenges further compound adoption problems. Steep learning curves and outdated interfaces reduce both buyer and supplier engagement, lowering platform ROI.

Limited mobile capabilities restrict 24/7 supplier responsiveness, while inflexible workflows fail to accommodate varying supplier maturity levels or category-specific needs.

Risk management suffers markedly with legacy systems that cannot properly track compliance or provide audit trails. When specification changes aren’t automatically acknowledged, production risks increase dramatically.

Limited APIs and non-standard data models also slow ecosystem expansion by hindering new supplier onboarding. Organizations frequently allocate about 60% of IT budgets to maintaining these outdated systems rather than investing in innovative solutions.

As competitive pressure increases, organizations must evaluate whether their legacy supplier portals have become liabilities rather than assets. Next-generation collaboration platforms offer real-time integration, AI-driven insights, and intuitive interfaces that dramatically reduce processing costs while improving supplier relationships.

Companies that fail to modernize risk falling behind more agile competitors who have embraced digital transformation across their supply chains.